Drones in Mining - Transforming the Mining Sector in India

9th Pixel Drones presents Aerial Mapping / Surveying for Mining sites employing fashionable drone technology. We have served Government and Private enterprises with grand success for improvement of efficiency and productivity of large mine sites. We even cater to project managers with stockpile management by quick, accurate, and real-time monitoring. Having satisfied Centimeter Level Accuracy, our GIS maps assist operation managers in the process of enhanced decision-making, allowing mines to be more productive and smart. Along with 30x faster data collection and 100% safety Drone Powered Surveys, smart management allows companies to keep track of stockpile management, Mining operations, Haul road optimization, water and sediment flow, mining exploration, mine blast assessment, etc.

All drones used by us are of premium quality and are outfitted with RGB sensors to acquire aerial data of mining sites. Our GIS experts intensify the data accumulated and portray them as Geotagged 3D maps, Contour lines, 3D Point cloud, Digital Elevation Models (DEM), Digital Terrain Models (DTM), or Digital Surface Models (DSM). These models mirror vital characteristics such as safety berm heights, crests and toes, road boundaries, slope length, elevation change, etc., which promote the improvement of worker and site-safety management.

With our drones obtaining more than 1000 data points and up to 350x more data points for one stockpile than traditional GNSS Surveys, our drones reflect highly accurate measurements. Paired with machine learning and geotagging of stockpiles, we provide volumetric calculations remitting a 99% accuracy guarantee.

We can help with

Stockpile management

Regardless of your work in the construction, mining, or aggregate sector, stockpile management is a must. Assigning your workforce for stockpile measurement can be hazardous, time-consuming, and costly. All stockpiles vary in shapes and sizes, making it challenging to estimate their volumes with high accuracy through traditional methods. Instead, the most optimal resolution would be to use high-quality drones to accumulate survey data. We advance stockpile volume estimation with 99% accuracy and further defeat issues concerning mine operations and personnel safety.

Better inventory tracking and financial reporting

With the experience and capabilities of our GIS experts, we transform extensive drone surveying data into 3d Models and 3d Point Cloud Maps of Stockpiles. These comprise numerous thousand data points that result in highly detailed Stockpile Volume calculations. The data is essential for mining companies for monthly tracking or year-end audits. We have assisted countless mining companies throughout India with systematic data collection through drone inspections, to advance inventory efficiency and conduct comprehensive mining operation management.

Mine Monitoring and Operation planning

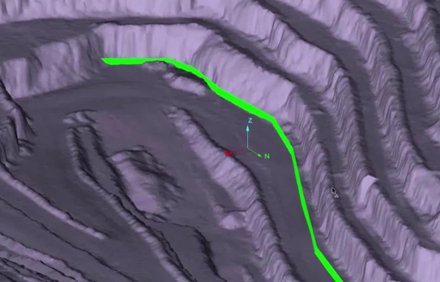

We encourage mining site managers to outline and maintain site operations efficiently. Our highly accurate drone data and GIS maps help design haul roads accurately, optimize traffic flow, and initiate team collaboration to ensure quick decision making to restore and retain safety.

Haul Road Optimisation

Periodic inspection and assessment of haul roads are vital to ensure the smooth running of mining operations and diminishing possibilities of a catastrophic event. As opposed to traditional methods, Drone Surveying preserves time, money, and acquires data that could never be obtained by human surveyors. Our skilled GIS crew produces various GIS maps like DTM, 3D Models, 3D Point Clouds, colour Slope Maps, etc. to provide excellent and valuable knowledge such as length, slope, and turning angles to mine managers. With this information, our clients can optimize the roads and significantly diminish fuel costs for moving materials out of mining sites.

Water and sediment flow

Monitoring water and sediment flow are essential as they can induce operation disruptions and hinder or stop the mining sites. With established Drone Mining Surveys, we have supported various mining companies to bypass such costly blunders. Our GIS team transforms data into Digital Elevation Maps (DEM), detailed Drone Imagery and machine learning to trace water flow and tailing pond. These representations solely assist managers in ensuring safety and adequate smooth water flow.

Tailings Dams Monitoring

Working with mining company planners, we promptly collect and present drone data to systematically monitor essential mine features such as slopes on Tailings Dams. Tailings are said to be highly toxic and probably radioactive as well; thus, mine managers and planners need to guarantee consistent maintenance of dams for utmost safety through UAV (Unmanned Aerial Vehicle) Inspections. Our drones can accumulate imagery of the dam to generate 3D Digital Elevation Models (DEM) of the dam for in-depth analysis. Timely monitoring of Tailings Dams conducted through aerial photography can go far to prevent tragedies like the Brumadinho site in Brazil.

Mining exploration

UAVs (Unmanned aerial systems) are continually growing as a less invasive approach for procuring authentic images for mineral exploration due to its safe, efficient, and sustainable nature. Our drones equipped with advanced RGB sensors, produce high-quality data, which further promotes our team to generate high-resolution orthophotos and DSM maps. The accumulated data is produced as a 3D model to learn and examine the structural control of mines. Drone Surveying for mining exploration is sufficiently economical and demands fewer on-foot exploration requirements. Drones further improve personnel and site safety.

Blast Planning & Assessment

One of the principal applications of drone technology can be seen in topography and mining operations, especially in planning, charging, and requiring blasting operations. This combo of unmanned vehicles and 3D Photogrammetry deliver High-Precision Inspections of the blasting area to make critical evaluations regarding safety. Our experts can replicate data such as GIS Maps, 3D models, and Photogrammetry to encourage clients to carefully examine the site to be drilled, extracted and guarantee sufficient resources. The detailed data obtained guide mine planners and project managers to plan thoroughly for future blasts, cut costs, time, and on-site drilling.

Deliverables We Provide

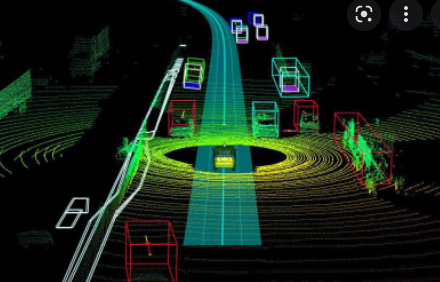

3D point cloud

Through drone data, we can mirror this information as a densified point cloud. In a 3D Point Cloud, each point comprises Geospatial (X, Y, Z) and several color information. 3D point clouds are said to produce precise data, excluding the distortion in 3D mesh models. 3D point cloud, which is known as industry-standard software, contributes highly detailed models for distance (slant and horizontal), area, and volume determinations.

Orthomosaic maps

An Orthomosaic is an extensive map-like image acquired from geometrically correcting an aerial photograph. These revisions include lens distortion, camera tilt, perspective, and topographic relief. Each pixel on the image comprises 2D and 3D geo-information (X, Y) and is capable of immediately obtaining precise measurements. Orthomosaic maps enable us to measure the area, volume, and distance of projects accurately.

3D textured mesh

Using the Point Cloud, we can produce the 3D Textured Mesh, a surface composed of triangles. It is an accurate reflection of the area's edges, faces, vertices, and texture captured by the drone and diminishes the gap among points on the point cloud and the surface. This model is fit for projects that require visual inspections or public involvement.

Digital terrain model (DTM)

Drone images are often utilized to generate Digital Terrain Models (DTMs), wherein each pixel comprises 2.5D data (X, Y, and Z value of the highest elevation). For an accurate DTM, there must be sufficient overlapping linking each collected image. The Digital Terrain model yields high-speed and efficient calculations.